STANDARD HOODS – CONSTRUCTED WITH PARTICULAR CARE

Our standard hoods stand out with their careful construction and adaptation to the requirements of thermal equipment.

Technical design (all models)

-

Manufactured with round corners, convenient for maintenance and cleaning.

-

Polished in V2A chromium-nickel steel. With a minimum material thickness of 1 mm.

-

Fully stainless welded, visually after-treated and polished.

-

Hoods deburred on the inside to prevent cuts.

-

Flame protection filter made of high-gloss polished V2A high-grade steel.

-

Integrated lighting with cover in anti-glare tempered glass.

Available as an option

-

Fire protection appliance: with automatic fire extinguisher system.

-

Built-in ventilator: 220 volts, infinitely variable adjustment.

Important information

The exhaust air system, consisting of selectively positioned hoods, is based on the implemented capacities, which must be matched to the thermal equipment positioned underneath.

The headrooms specified in our dimension sketches should be understood as minimum heights. Structurally necessary deviations should be discussed with EMK.

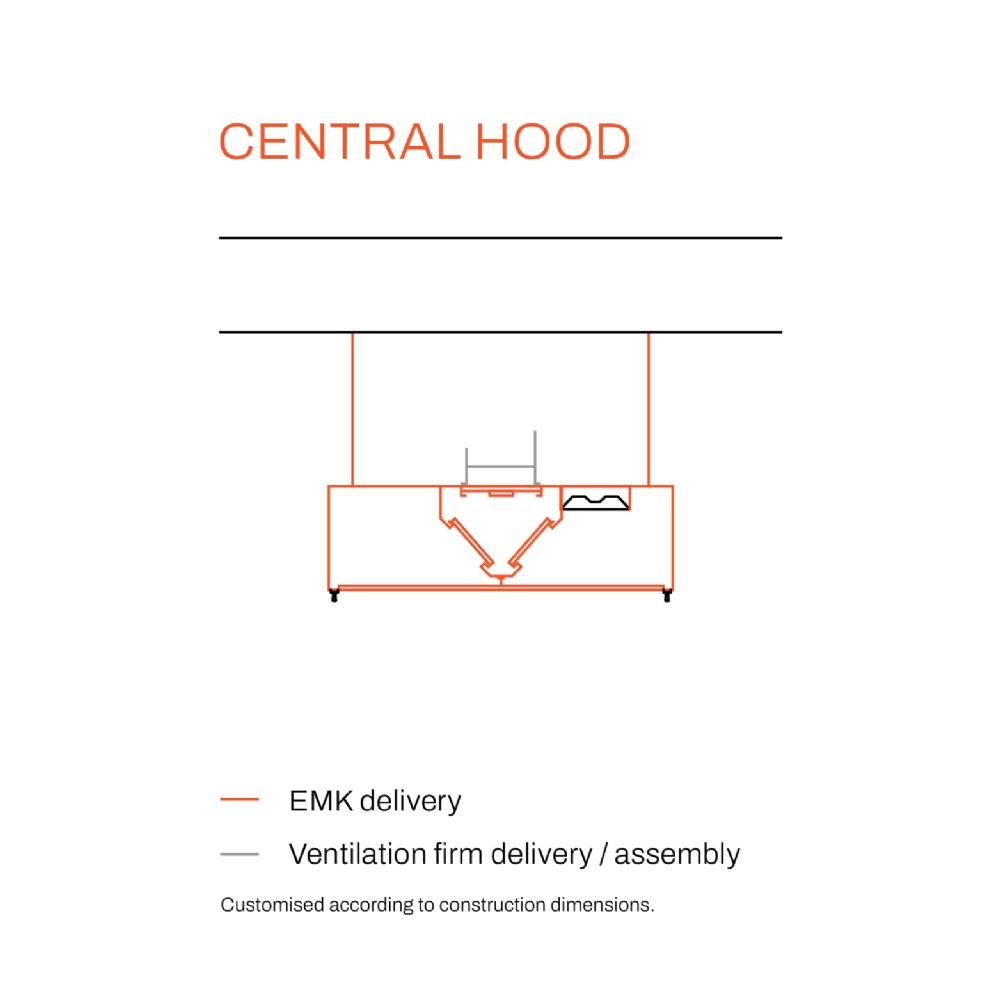

Central hood

The hood consists of a double-inlet exhaust air duct with built-in eddy current filters made of high-grade steel. On one side along the suction basket, LED lighting is integrated, which is equipped with a safety glass covering. In addition, a circumferential grease trap channel including an outlet valve with collecting container and an FC-type fat separator is incorporated.

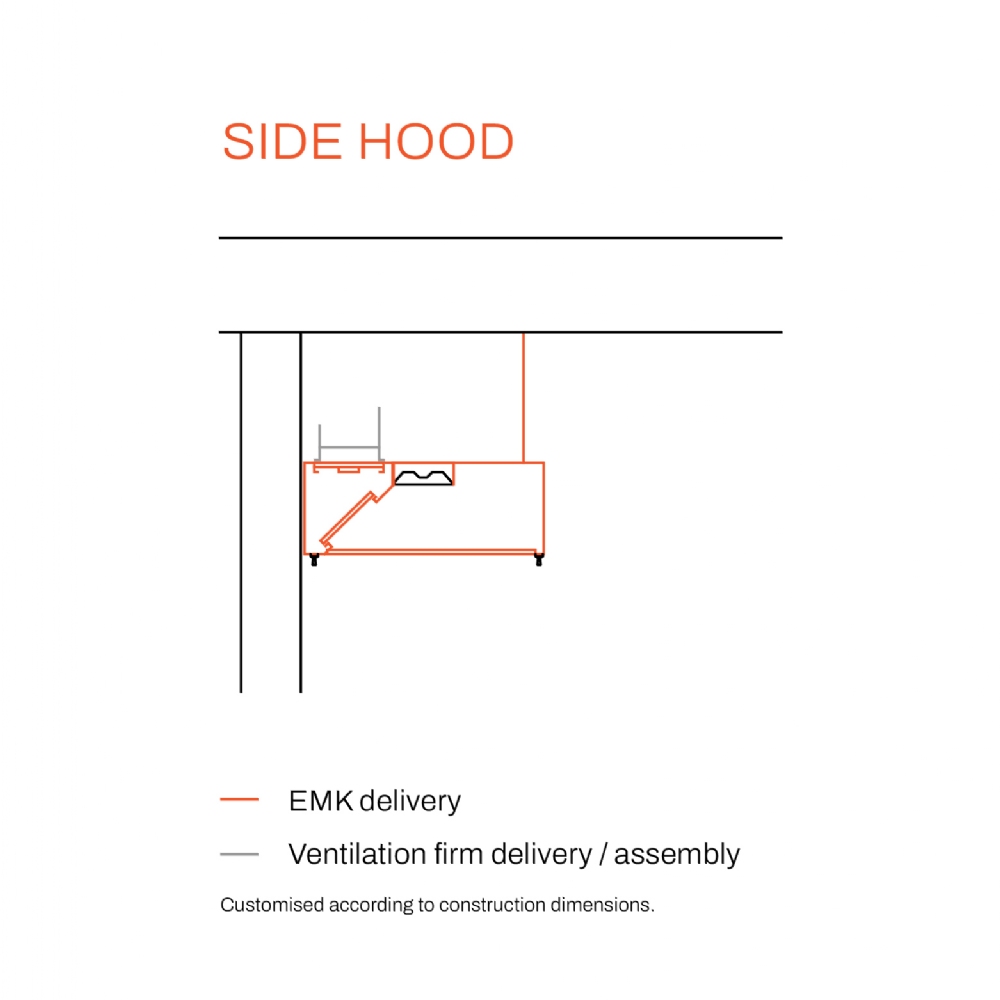

Side hood

The hood consists of a single-inlet exhaust air duct with built-in eddy current filters made of high-grade steel. On one side along the suction basket, LED lighting is integrated, which is equipped with a safety glass covering. In addition, a circumferential grease trap channel including an outlet valve with collecting container and an FC-type fat separator is incorporated.

The side hood is not suitable for thermal equipment that generates a lot of steam. In the case of low headroom, there is the danger of a vortex being created, which can lead to steam escaping.

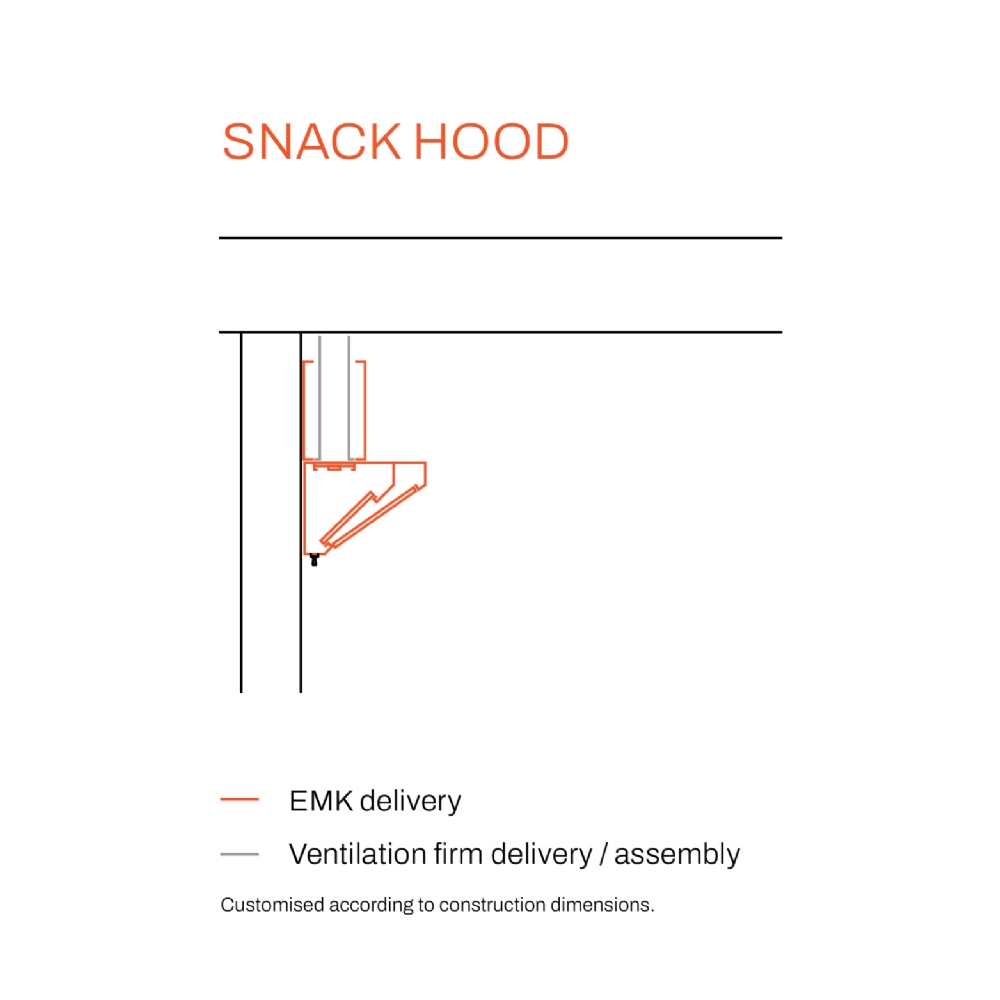

Snack hood

Selective extraction prevents the wall tiles from becoming soiled. Particularly suitable as an addition to exhaust air ceilings positioned at a higher level.

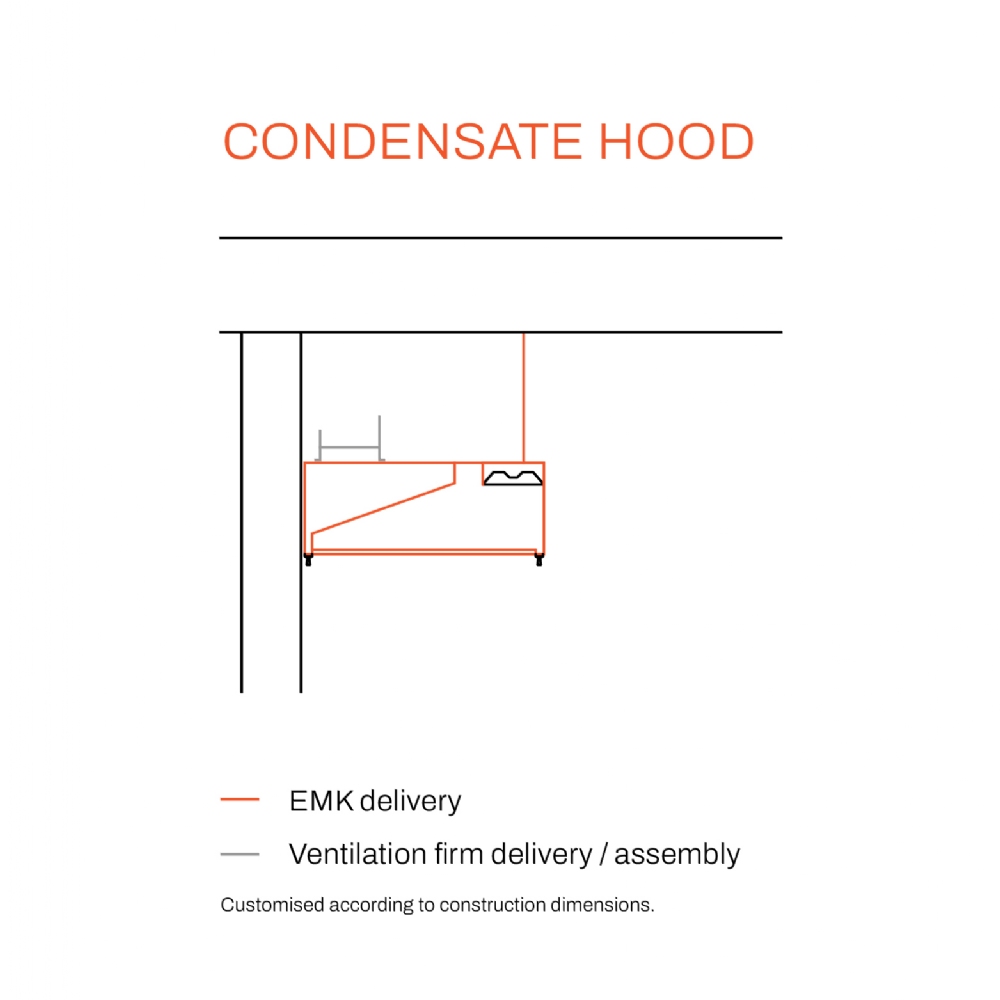

Condensate hood

Thanks to its low air resistance and the condensate deflector, this hood is especially suited for hood dishwashers. The surge of steam is quickly and efficiently suctioned off.